Hip Prothesis

In total hip prosthesis, to minimize chances of resorption of femur, matching the stiffness of the femur and the stem of the prosthetic implant is essential. Although more than 150,000 total hip replacement operations are performed annually in the U.S., one of the major unsolved problems in this important orthopedic surgery has been the complete mismatching of stiffness of the femur and the prosthesis. At present, commercially available hip prostheses are made of cobalt-chrome and stainless steel stems with a stiffness which can be 20 to 30 times that of cortical bone. It has been clearly established that this mismatch leads to resorption of bone and eventual aseptic loosening of the implant. This causes severe pain and clinical failure necessitating repeat surgery. About 10 to 15% fail within five to seven years. Matching of bone and implant stiffness would substantially decrease the chances of resorption of bone and eventual failure. What is needed is a material with high strength and spatially or locally varying mechanical properties along the boundary of the prosthesis. This is an inherent quality that the composite materials can offer.

Advanced

composite materials offer the potential to tailor component properties

by selecting material ingredients and spatially controlling ingredient

composition and configuration. This allows one to control the prosthesis

stiffness modulus to closely approximate the stiffness of the natural bone

at the interface. Development of composite hip prostheses currently focuses

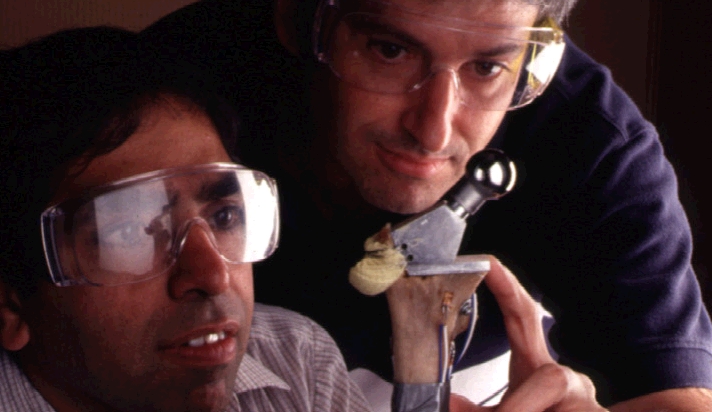

on the use of continuous-fiber composites. Four seniors this year are engaged

in designing, manufacturing a prototype of a hip-implant using the RTM

process. They will also test the implant for strength, stiffness, fatigue

and impact properties.

Advanced

composite materials offer the potential to tailor component properties

by selecting material ingredients and spatially controlling ingredient

composition and configuration. This allows one to control the prosthesis

stiffness modulus to closely approximate the stiffness of the natural bone

at the interface. Development of composite hip prostheses currently focuses

on the use of continuous-fiber composites. Four seniors this year are engaged

in designing, manufacturing a prototype of a hip-implant using the RTM

process. They will also test the implant for strength, stiffness, fatigue

and impact properties.